The plastic bag industry plays a significant role in global commerce. In 2022, the market for plastic bags was valued at approximately $23 billion and is projected to reach $30 billion by 2026. This growth highlights the demand for efficient production methods. Companies must focus on ways to produce plastic bags that reduce costs while maintaining quality.

To produce plastic bags effectively, it is essential to understand current trends and technologies. Advanced manufacturing techniques can enhance production speeds and minimize waste. However, many businesses still struggle with outdated processes that lead to inefficiencies. Implementing modern practices can significantly cut down production time, increase profitability, and lower environmental impact.

Despite advancements, the industry faces challenges. Environmental concerns continue to mount as consumer preferences shift towards sustainable alternatives. Therefore, manufacturers must reflect on their practices and adopt greener methodologies. Efficient production of plastic bags is not just about speed; it also involves responsibility and innovation in materials used. Adapting to these trends can ensure long-term success in a competitive market.

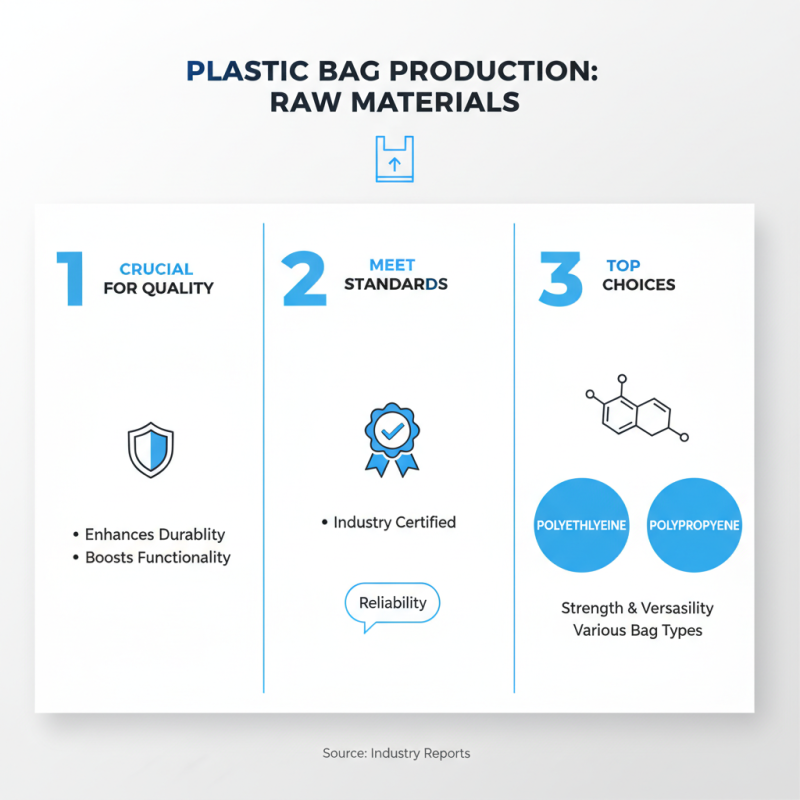

Choosing quality raw materials is crucial in plastic bag production. A good selection can enhance durability and functionality. Look for materials that meet industry standards. Consider polyethylene and polypropylene, as they offer excellent strength and versatility. These materials are often used for various bag types.

Recycling plays a significant role too. Using recycled materials can lower costs. However, always verify the quality of recycled raw materials. Bad quality can lead to weak bags. Assess the supplier's credibility. Ask for samples and test the materials before making large orders. It is also wise to stay updated on material innovations.

Monitoring the sourcing process is essential. Local suppliers can reduce transport costs. However, they may not always provide the best quality. Striking a balance between quality and cost is key.

There might be a temptation to cut corners with cheaper materials. However, this can backfire in the long run. Consider the impact of your choices on the environment. Each decision can shape the future of the plastic bag industry.

Optimizing production processes in plastic bag manufacturing is crucial for efficiency. Reports show that around 30% of production time is often wasted due to outdated machinery. Upgrading to modern, automated systems can drastically reduce downtime. The integration of real-time data tracking can streamline operations. This helps to identify bottlenecks quickly and improve workflow.

Machine settings also play a significant role. Small adjustments can lead to better output quality. Often, companies find that slight variations in temperature can enhance film characteristics. This kind of fine-tuning is essential. It can boost production rates by up to 25% according to industry analyses. Regular training sessions for staff are necessary. Skilled operators can optimize these settings further.

Recycling waste during production is another method that needs emphasis. About 10% of materials typically go unused. Implementing a robust recycling program for off-cuts can lead to significant cost savings. However, this practice is not yet standard in many facilities. Continuous improvement in these areas can lead to substantial gains in efficiency, revealing the industry's potential for growth.

| Tip Number | Tip | Description | Expected Outcome |

|---|---|---|---|

| 1 | Streamline Material Handling | Use automated systems for loading and unloading materials. | Reduced downtime and increased production speed. |

| 2 | Implement Quality Control Checks | Regular inspections throughout the production process. | Minimized waste and improved final product quality. |

| 3 | Optimize Machine Settings | Regularly calibrate machines for optimal performance. | Enhanced machine efficiency and reduced energy consumption. |

| 4 | Train Employees Regularly | Invest in training for operators on best practices. | Higher productivity due to skilled workforce. |

| 5 | Maintain Equipment | Scheduled maintenance to prevent machine failures. | Reduced unplanned downtime and repair costs. |

| 6 | Reduce Changeover Times | Standardize processes to minimize setup time. | Increased flexibility and throughput in production. |

| 7 | Utilize Advanced Technology | Incorporate automation and smart technology in production. | Higher efficiency and reduction in human error. |

| 8 | Implement Lean Manufacturing Techniques | Focus on eliminating waste and optimizing workflow. | More efficient use of resources and reduced costs. |

| 9 | Monitor Production Metrics | Track KPIs like throughput and defect rates. | Data-driven decisions to enhance operations. |

| 10 | Enhance Supply Chain Management | Optimize inventory management and supplier relationships. | Improved material availability and reduced lead times. |

The production of plastic bags can benefit greatly from advanced technology. Speed and efficiency are crucial in this industry. Automation is one of the best methods to enhance production rates. Efficient machinery can operate around the clock, reducing downtime. This leads to increased output with minimal human intervention. However, the initial investment can be significant.

Monitoring systems also play an essential role. Real-time data helps identify bottlenecks in the production line. This feedback allows for immediate adjustments. Without such systems, inefficiencies can persist, impacting overall productivity. Yet, too much reliance on technology can lead to complacency. Human oversight remains vital for quality control.

Other technologies, like 3D printing, are emerging. They can create custom molds quickly. This reduces lead times but also prompts questions about scalability. Not every operation needs such innovation. The challenge is to balance tech with practicality. Embracing technology is good, but it should align with specific needs. Constant reflection on what works and what doesn't is necessary in this fast-evolving industry.

Training staff effectively is crucial in boosting efficiency in plastic bag production. Engaged employees have a direct impact on the production line. Investing in hands-on training enhances their skills. Use real scenarios to simulate production challenges. This helps them think critically and find solutions quickly.

Incorporating feedback mechanisms can also improve processes. Conduct regular reviews to identify areas for improvement. Sometimes, staff may need guidance, as they might stick to outdated practices. Encourage an atmosphere of open communication. Workers should feel comfortable sharing their ideas and frustrations. Small changes can lead to significant results.

Production operations often face unexpected issues. For example, machinery malfunctions can cause delays. Training should address how to handle emergencies effectively. It's not just about speed, but also quality. Regular workshops on best practices ensure staff stay updated. Mistakes happen, but learning from them is essential. Providing a supportive environment encourages continuous improvement.

This chart illustrates the expected percentage improvements in efficiency for various measures taken in the plastic bag production process. The highest impact is expected from staff training, followed by quality control measures.

Plastic bag manufacturing can significantly impact the environment. Sustainable practices are essential to reduce waste in this sector. According to a report by the Ellen MacArthur Foundation, around 8 million tons of plastic enter the oceans each year. This highlights the need for manufacturers to embrace eco-friendly practices.

One effective tip is to optimize production processes. Improving machinery efficiency can reduce energy consumption. Regular maintenance ensures machines operate smoothly, minimizing excess waste. Switching to biodegradable materials is another crucial step. These alternatives can reduce pollution and degradation.

Additionally, recycling programs within manufacturing facilities can create a closed-loop system. Industrial-scale recycling can reduce raw material costs by up to 30%. Another tip is to educate employees about sustainability. Enhancing awareness can lead to more mindful production practices. Every small effort counts. The goal is to align production with sustainable targets for a healthier planet.